ALGLASS FC VM 2000 BURNER

ALGLASS FC VM range - Oxy-fuel burner for glass applications

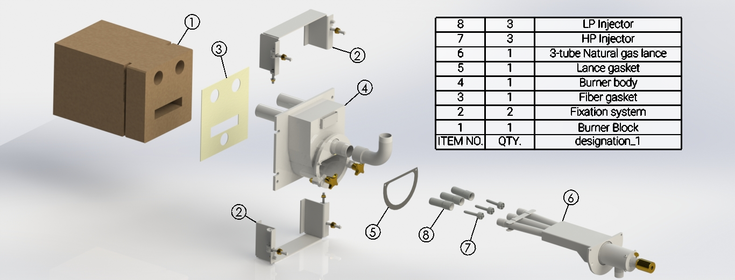

The ALGLASS FC VM burner is a non-water-cooled oxy-fuel burner especially designed for continuous melting furnaces. This burner is particularly appropriate for most glass-type applications. The ALGLASS FC VM burner uses a design (Patent pending) where fuel and oxygen mix outside the burner block. Fuel and oxygen are introduced into the furnace through a unique configuration of injectors that produces a highly luminous flame up to three times wider than conventional oxy-fuel burners. The fuel is distributed, at the bottom of refractory burner block, among three double concentric injectors arranged in a fan-shaped configuration, so that the streams of fuel form a wide sheet of gas in the furnace. Oxygen is injected at lower velocity from two injectors located at the top of the block, that direct the oxygen flow towards the jets of fuel. The use of double concentric injectors with inner injection (high momentum) and outer injection (low momentum) and a built-in valve positioned upstream of the natural gas lance allow to tune the momentum of the gas stream between low momentum (outer injection) and high momentum (inner injection). This design is used to adjust flame shape and more generally combustion characteristics.

General information

|

Model

|

ALGLASS FC VM 2000

|

| Max. Comb. Cap | 3600 kW |

| Nom. Comb. Cap. | 2000 kW |

| Min. Comb. Cap. | 600 kW |

Spare parts

|

Spare part designation

|

CNPL reference for order

|

| Burner body | 1478 7010 0000 |

| Brackets | 1478 7100 0000 |

| Refractory block (ERMOLD) without Fuel Oil hole | 1478 7400 0000 |

| Refractory block (ZM9-27V) without Fuel Oil hole | 1478 7800 0000 |

| Fuel gas lance with valve for controlling flows (not equipped with injectors) | 1478 7000 0010 |

| Complete set of Natural gas injectors (3 for inner injection and 3 for outer injection) | 1478 7000 0012 |

| Ceramic fiber gasket | 1478 7000 0005 |

| Flat Viton sheet gasket | 1478 7000 0006 |

User Manual

-

EN - ALGLASS FC VM BURNER Models

Download the document PDF (1.11 MB)

Find your Safety Data Sheet

-

Bulgaria

Download the document PDF (504.58 KB) -

France

Download the document PDF (156.26 KB) -

Germany

Download the document PDF (156.06 KB) -

Greece

Download the document PDF (172.3 KB) -

Italy

Download the document PDF (343.06 KB) -

Poland

Download the document PDF (181.09 KB) -

Portugal

Download the document PDF (78.27 KB) -

Spain

Download the document PDF (313.74 KB) -

Switzerland

Download the document PDF (328.52 KB) -

UK

Download the document PDF (156.01 KB)

-

China

Download the document PDF (673.76 KB)Download the document PDF (264.91 KB) -

Russia

Download the document PDF (792.72 KB) -

Japan

Download the document PDF (268.45 KB)

-

Turkey

Download the document PDF (285.95 KB)

-

USA

Download the document PDF (930.32 KB)